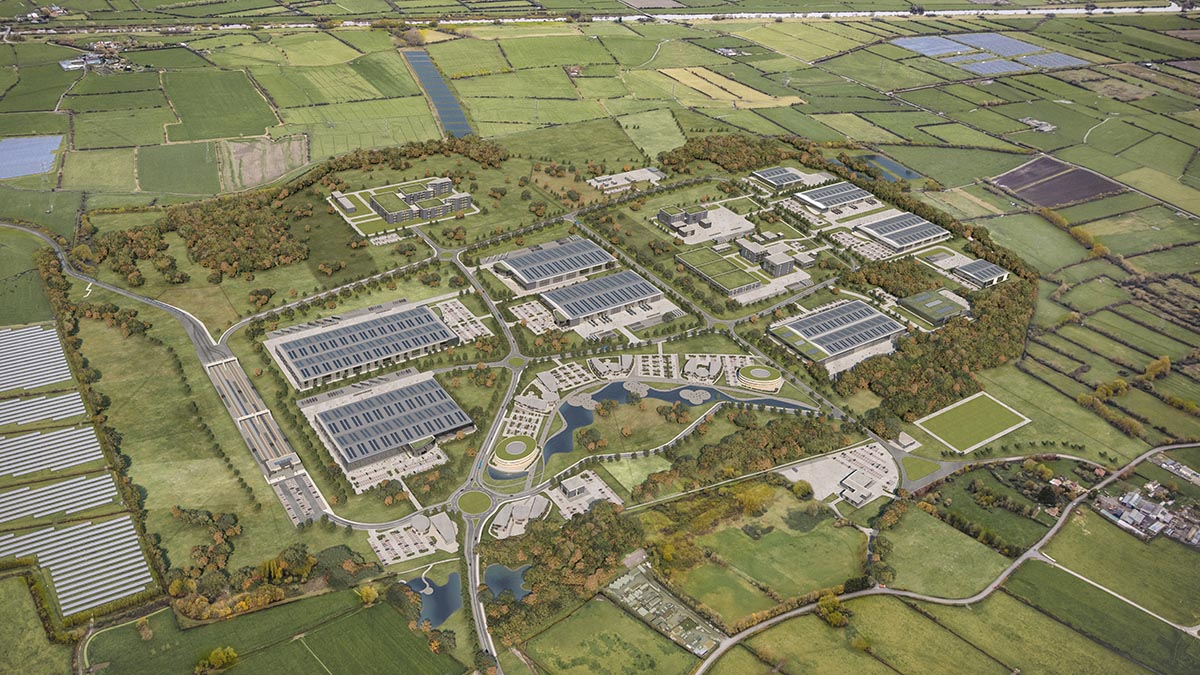

The UK’s first planned gigaplant, has secured millions in funding from the Government.

Britishvolt’s Northumberland Gigafactory scheme has received a principal offer of £100million through the Automotive Transformation Fund (ATF), a funding programme that supports the electrification of the UK auto industry.

Once the giant plant is complete, it is expected to produce enough batteries for 300,000 electric vehicles every year. In addition, the Gigaplant will provide an estimated 3,000 highly skilled jobs direct to the local economy and a further 5,000 jobs in the broader supply chain.

The initial Government support is anticipated to be able to unlock further financial backing from private investors with Tritax and Abrdn expected to back the project to the tune of £1.7billion.

Speaking about the funding for the huge project in the Northeast of England, Prime Minister Boris Johnson said of the plan:

“Britishvolt’s plan to build a new Gigafactory in Northumberland is a strong testament to the skilled workers of the North East and the UK’s place at the helm of the global green industrial revolution.”

“Backed by government and private sector investment, this new battery factory will boost the production of electric vehicles in the UK, whilst levelling up opportunity and bringing thousands of new highly-skilled jobs to communities in our industrial heartlands.”

The Business Secretary, Kwasi Kwarteng added to the PM’s statement, saying:

“Today’s news is a major boost for Britain and a resounding vote of confidence in the North East economy.”

“Britishvolt’s planned Gigafactory will not only enable the UK to fully capture the benefits of a booming electric vehicle market, but will bring thousands of highly-skilled, well-paid jobs to the North East.”

“In this global race between countries to secure vital battery production, this government is proud to make the investment necessary to ensure UK’s retains its place as one of the best locations in the world for auto manufacturing.”

In addition to the re-industrialisation, creation of skilled jobs and drive toward electrification of the nation’s transport, the EV battery plant will play its part in helping the country to achieve its Net Zero Strategy.

Peter Rolton, Britishvolt’s Executive Chairman concluded:

“This is a truly historic day and marks the start of a truly exciting move towards a low carbon future. One with Britishvolt batteries at the very centre of that strategy.”

The strategic value of building and providing electric vehicle batteries is paramount to the success of the UK automotive industry. As EV batteries are large and heavy, it makes economic sense to supply electric car batteries from as local a production point as possible. In a similar move last year, Envision announced a joint venture with Nissan to supply battery systems to their car plant in Sunderland.

Part of the Brexit deal has meant that UK-built cars sold in Europe will require a significant proportion of parts to be sourced in the UK and EU. That makes it attractive for automotive manufacturers to set up production in this country.

Caltest Instruments are your ideal partner in the electrification of transportation. We provide EV battery testing equipment, Vehicle to Grid (V2G) testing devices, Electric Vehicle Testing Systems and equipment to ensure the integrity of your battery management systems.

Call Caltest on 01483 302 700 or complete the contact form for bespoke systems consultation, sales, hire and calibration, and the best advice on the most suitable equipment for your electrification project.

Leave a reply