The Most Advanced EV Battery Management System? (BMS)

Electric Vehicle Battery Management Systems (BMS) are expected to take a forward leap as Eatron Technologies and WMG win funding for their COBRA project.

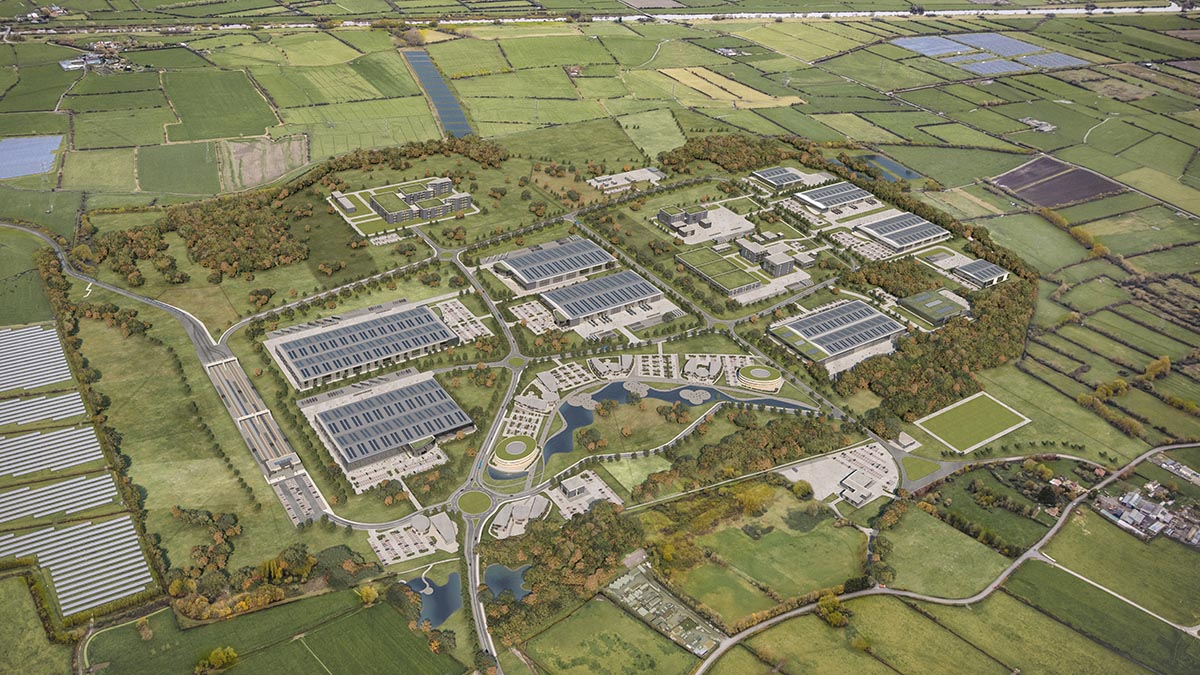

Eatron, a software company specialising in electric and autonomous vehicles, has teamed up with WMG, a division of the University of Warwick, based at the campus’ International Manufacturing Centre.

COBRA is the partnership’s innovative Cloud/Onboard Battery Remaining useful life Algorithm project. Remaining Useful Life (RUL) of EV batteries is key to Battery Management Systems and the COBRA project could lead to the UK becoming one of the most advanced BMS providers in the world.

Utilising machine-learning, project COBRA is expected to deliver RUL with an accuracy of over 90%. The advanced battery diagnostics algorithms will ensure that both EV battery manufacturers and integrators will benefit greatly from their technology. Original Equipment Manufacturers (OEMs), UPS suppliers and other providers all stand to gain from advanced BMS.

From a broader perspective, RUL algorithms can help BMS extend EV battery life and even provide improved second-life applications.

Speaking about the COBRA project, Dr Dhammika Widanalage from WMG at the University of Warwick, said:

“We are delighted to work with Eatron technologies on the COBRA project and look forward to using our novel battery ageing technology to test out their algorithms in their battery management system.

“If their algorithms mean consumers can get more out of their EV battery, then it’s possible more people may be inclined to buy one, therefore helping the UK pave the way to a cleaner greener zero-carbon future.”

The funding for project COBRA came from the Faraday Battery Challenge at UK Research & Innovation. Tony Harper, Challenge Director at Faraday Battery Challenge added:

“Since 2017 the Faraday Battery Challenge has been supporting the UK’s battery companies to produce batteries that are more cost effective, more efficient, charge faster and can easily be recycled. This new round of funding has enabled us to support companies, like Eatron Technologies, across the battery supply chain and build on the UK’s world class research and innovation.”

Electric vehicles are expected to become ever more common on UK roads with an anticipated 1.8 million to be sold in 2030. That figure amounts to 64% of all expected car sales according to the Faraday Institute.

Caltest Instruments are a leading supplier of battery test equipment for EV manufacturers. See our range of battery cell test equipment.

Discuss the right solution for your project by calling our consultants on 01483 302 700 or complete the contact form.

Leave a reply